Call Us08045801492

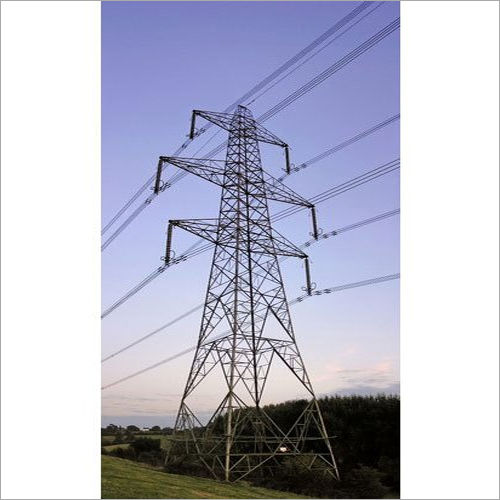

Transmission Tower

68 INR/Kilograms

Product Details:

- Product Type Transmission Tower

- Material Galvanized Steel

- Capacity Up to 500 kV

- Protection Corrosion Resistance, Weather Proof

- Application Power Transmission, Electrical Grid Infrastructure

- Size Customized as per requirement

- Weight Varies as per size and design

- Click to View more

X

Transmission Tower Price And Quantity

- 68 INR/Kilograms

- 1 Kilograms

Transmission Tower Product Specifications

- Up to 500 kV

- Galvanized Steel

- Corrosion Resistance, Weather Proof

- Varies as per size and design

- Silver/Grey

- Customized

- Power Transmission, Electrical Grid Infrastructure

- Customized as per requirement

- Transmission Tower

Transmission Tower Trade Information

- 1 Kilograms Per Day

- 10 Days

Product Description

Transmission Line Tower is a large skeletal structure which is used to construct heavy duty electric power transmission systems to hang wired conductors at certain heights. This heavy structure is fabricated by using premium class mild steel members that are connected together with the help of heavy mechanical fasteners to provide higher durability. Transmission Line Tower is designed as per the constructional standards that make them capable to resist harsh outdoor conditions.

Engineered for Durability and Safety

Constructed with galvanized lattice steel, our transmission towers offer excellent weatherproofing and enduring performance, even in areas with high humidity or pollution. The hot dip galvanized surface treatment ensures exceptional corrosion resistance and long service lifeover 30 years with minimal upkeep, far surpassing industry norms.

Flexible Design and Application

Available in standard heights from 15m to 50m and customizable to unique site requirements, these towers are adaptable for varied grid configurationsfrom single to double-circuit cross arms. Each tower is pre-fabricated for efficient transport and quick on-site assembly, optimizing installation in diverse Indian terrains.

FAQs of Transmission Tower:

Q: How are your lattice transmission towers installed on-site?

A: The towers are delivered as pre-fabricated sections, allowing for straightforward on-ground assembly. Installation involves bolting together the lattice components using high tensile, galvanized fasteners for structural integrity, followed by mounting as per site-specific dimensions and protocols.Q: What makes hot dip galvanized steel ideal for transmission towers in harsh environments?

A: Hot dip galvanization forms a resilient zinc coating protecting the steel from corrosion and weathering, providing exceptional durability even in coastal, industrial, or high-humidity regions. This ensures the towers integrity and performance over decades with low maintenance needs.Q: When should periodic inspections be conducted for these towers?

A: Periodic inspections are recommended at regular intervalstypically annually, or more frequently in regions with severe weather exposure. Routine checks help ensure long-term safety, compliance, and optimal performance throughout the towers service life.Q: Where are these towers most commonly used?

A: These towers are widely used across India in power transmission networks, substations, and for expanding electrical grid infrastructure, thanks to their robust, weather-resistant build and customizable design options.Q: What is the benefit of compliance with standards like IS 802, IEC 60826, and ASTM A123/A123M?

A: Adhering to these international and national standards assures customers of product safety, reliability, and interoperability within transmission networks, supporting quality benchmarks recognized by utilities and regulatory agencies.Q: How does the tower design accommodate different electrical capacities and configurations?

A: With options for single or double-circuit cross arms and extended height or size customization, the towers suit various voltage capacitiesup to 500 kVenabling flexible integration into new or existing power grids.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Transmission Line Tower' category

"We are accepting bulk order quantity only."