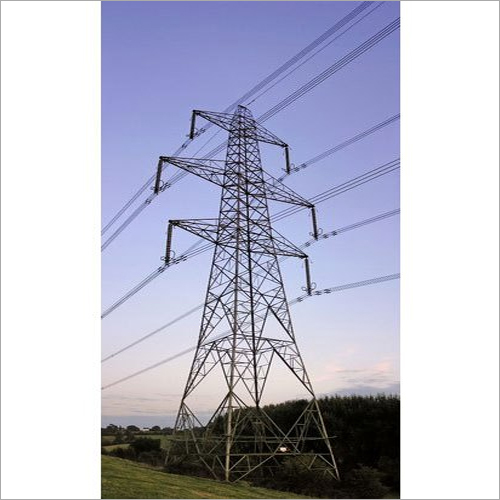

Transmission Line Tower

Product Details:

- Product Type Transmission Line Tower

- Material Galvanized Steel

- Capacity Up to 765 kV

- Output Power N/A (Structural Component)

- Protection Corrosion resistance

- Output Voltage N/A (Depends on line)

- Output Current N/A (Depends on line)

- Click to View more

X

Transmission Line Tower Product Specifications

- N/A (Depends on line)

- Electrical transmission line support

- Customizable as per requirement

- Silver (Hot Dip Galvanized)

- N/A (Structural Component)

- Up to 765 kV

- Corrosion resistance

- Varies as per design/specification

- Transmission Line Tower

- N/A (Depends on line)

- Galvanized Steel

- As per design specification

Product Description

Transmission Line Tower is a rigid vertically standing structure that is designed as per the structural and architectural standards. It is in high demand within power distribution in between power plants and cities. This heavy duty structure is also provided with insulators and connectors to rigidly clamp wired conductors. The offered Transmission Line Tower is provided with a paint coating that functions as a shield for the prevention surface damages due to harsh climatic conditions. It comes in various customizable sizes as per the customer demands. Get this heavy duty structure at a reasonable price range.

Advanced Structural Design

Our lattice towers utilize a modular design based on bolted connections, facilitating straightforward assembly and future adjustments. With the flexibility to produce square, rectangular, or custom shapes, the structure can be tailored to match specific electrical transmission requirements, ensuring both strength and efficiency on any site.

Superior Longevity and Protection

Hot dip galvanization provides exceptional corrosion resistance, safeguarding your infrastructure against harsh environmental conditions. This protective finishing, combined with high tensile steel bolts and nuts, contributes to a tower design life of more than 40 years, reducing replacement frequency and maintenance costs over time.

Custom Solutions for Every Project

These transmission line towers are manufactured to precise specifications in terms of size, shape, and capacity, supporting voltages of up to 765 kV. Regardless of the project scale, our towers are designed to integrate seamlessly with existing and new electrical grids, providing reliable support for overhead power lines across diverse terrains.

FAQ's of Transmission Line Tower:

Q: How are transmission line lattice towers assembled on-site?

A: Transmission line lattice towers are assembled using modular bolted sections. This method allows for quick and efficient assembly at the installation site, minimizing construction time and enabling easy transportation of individual components.Q: What are the main benefits of hot dip galvanized finishing for these towers?

A: Hot dip galvanization offers long-lasting protection against corrosion, even in extreme weather conditions. This finishing process contributes significantly to the tower's durability, reducing maintenance needs and extending the overall design life beyond 40 years.Q: When should I opt for a custom-shaped transmission tower?

A: Custom-shaped towers are ideal when the site or electrical requirements demand specific configurations, such as non-standard spans, special route alignments, or unique structural needs. Our manufacturing process accommodates these variations for optimal project support.Q: Where are these transmission line towers typically used?

A: These towers are commonly installed in electrical transmission networks, supporting high-voltage overhead power lines. They are suited for a variety of terrains across India, from urban settings to challenging rural environments.Q: What is the process for determining the size and capacity of my lattice tower?

A: The size and capacity are tailored to your project's voltage requirements-up to 765 kV-as well as the specific length of the span, environmental loads, and site-specific factors. Our engineering team collaborates with clients to finalize all technical specifications.Q: How do high tensile galvanized steel bolts and nuts enhance tower performance?

A: Using high tensile galvanized steel bolts and nuts increases the structural strength and stability of the tower while maintaining corrosion resistance. This results in a safer and longer-lasting infrastructure element.Q: What are the advantages of using a concrete base foundation for these towers?

A: A concrete base provides sturdy anchorage and stability for the lattice tower, ensuring safe support for heavy wind loads and preventing structural shifting or failure during adverse weather conditions.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Transmission Line Tower' category

"We are accepting bulk order quantity only."